Machine Vision

Machine vision is a technology which has been available since the 1980s, and is widely deployed on manufacturing production lines. It has been put to good use in the UK in at least two separate railway inspection applications: trains and tracks. These developments were undertaken by two different companies, using different approaches and for differing reasons, but with the same overriding objective: to safely and rapidly inspect equipment, consistently and repeatably, to identify and quantify its state, allowing engineers and maintenance technicians to focus on fixing instead of finding. They enable better prediction and targeting of maintenance for better planning of work and lower maintenance costs.

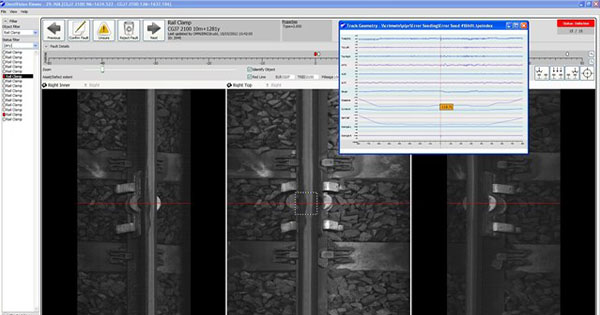

Plain Line Pattern Recognition (PLPR) has been developed by Network Rail originating with a proof of concept by Loughborough University. This concept was developed into a production system by Omnicom Balfour Beatty. It is a train-borne high-speed system using an array of cameras working at up to 70,000kHz, supported by lights and lasers to capture images of the track every 0.8mm at up to 125mph. It is integrated with Track Geometry measurements and applies algorithms to automate the examination of images to flag potential faults with the joints, track condition and fastenings.

Work continues to refine the system, applying deep machine learning to filter out the large number of false reports of faults. This will allow inspectors to better target their attention and reduce the time to process data and highlight faults. PLPR has been rolled-out on 10,000 miles of track across the mainline network, saving £millions and replacing inspections for these faults previously carried out by walking the track. It also forms a recent chapter in the story to dramatically reduce broken rails, helping to keep Britain’s railway one of the safest in Europe.

Much rail vehicle maintenance involves inspection and measurement to ensure that equipment remains within specified ranges, or that things are present and undamaged. Such checks are always subject to a certain amount of human error and frailty when working in difficult conditions, typically at night; the information gained is used to determine whether wearing components, such as brake pads, brake discs or wheel treads and flanges need further attention, and whilst such items are consumables, their cost is high.

MRX, since acquired by Siemens, developed a modular Vehicle Equipment Monitoring System (VEMS), which could be installed at a customer’s site. In addition to wheel and brake conditions, it could also check axle bearing temperature, pantograph condition and vehicle exterior condition. Background processing collates detailed onboard equipment statuses to permit the introduction of condition-based maintenance as a standard operating mode, relying on technology to detect and warn maintenance crews of developing conditions or failures before they actually occur. The combined system is called AVIS and is being used on a number of fleets.

September 2020

Back