Intelligent wagons: a low cost, flexible alternative to Digital Automatic Couplers

The intelligent wagon concept represents a major step forward in rail freight safety and operations. Its development was pursued by a consortium led by Railfreight Consulting.

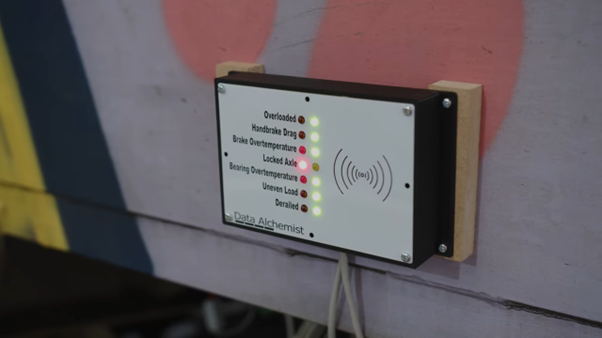

These wagons accommodate a range of different remote condition monitoring sensors depending on the operational need. The intelligent wagon reports insights from sensors to the driver or elsewhere in real-time so appropriate action can be taken in a timely fashion.

To achieve this, the intelligent wagon solution uses a ‘powerline’ where a power cable supplies power down the consist. These cables also convey digital signals from the sensors to locomotive cab, enabling relevant messages to reach the driver.

Power cables were chosen as they are a cheap, reliable solution with low maintenance requirements and are suitable for use when hauling dangerous goods. This provides a low-cost flexible alternative to Digital Automatic Couplers (DAC). The GB specific cost-benefit analysis for DAC concluded that there are insufficient benefits to justify the large costs associated with their deployment, so pursuing alternatives is critical.

In early 2024 a demonstrator rake of six modified JNA bogie box wagons, owned by Ermewa and leased to Tarmac, was tested at Barrow Hill Roundhouse. The trial fitted sensors to provide derailment, handbrake status, and loading notifications (full, empty, asymmetric loading). The testing successfully demonstrated all of these.

In addition, the core infrastructure of the intelligent wagon concept provides immediate fault reporting on train separation, enables auto-consisting, and is a bearer of ETCS level 3 compliance. This means wagons will be ready for future signalling system upgrades.

May 2024