Topic:

Rail-Wheel Interface Research- Friction Management and Low Adhesion

Summary:

Rail-Wheel Interface research has developed from the Tribology centre of expertise at Sheffield. We conduct World leading research on friction through the EPSRC Programme Grant “Friction: The Tribology Enigma” and a strong part of this is centred around wheel/rail interface friction management. We have a strategic partnership with RSSB and RAEng on wheel/rail interface low adhesion management through Prof Lewis’ Research Chair. Areas of activity include analysis of fundamental aspects of friction, in particular low adhesion mechanisms relating to “wet-rail” and leaf layers. We study friction modifiers, lubricants and traction enhancers such as sand and traction gels. Work is carried out the assess their application, pick-up and carry-down. We also develop friction models and adhesion forecasting tools.

Project examples:

*RSSB Sanding consist project (Dec 2020 – Nov 2021), RSSB funded project (T1149) to extend a low adhesion creep force model (LILAC) (Oct 2018 – Jul 2019), RSSB & Network Rail: Establishing benchmarks tests for TOR products (Mar 2019 – May 2021), FRA: Modeling the effects of top of rail friction modifiers in the wheel/rail interface (2017-18)

Topic:

Rail-Wheel Interface Research

Summary:

Rail-Wheel Interface research has developed from the Tribology centre of expertise at Sheffield. We conduct World leading research, across multiple contracts with RSSB, Network Rail, London Underground, plus others. Areas of activity include experimental analysis of damage mechanisms; analysis of the role of microstructure; wear prediction, rolling contact fatigue modelling; innovative methods for reducing wear and damage such as additive manufacture (e.g. laser cladding). We are also involved in incident investigation.

Project examples:

*Network Rail In2Track2 project on S&C friction modification (July 2020 – August 2021), MCL TopTrack Project on wear of crossing nose material (Nov 2019 – Oct 2022), ViF funded TriboWearTherm project on wheel and rail wear prediction (Sept 2018 – Aug 2021), Characterisation of Rail Steel for In-Service Life Prediction (EPSRC, British Steel, 2018-22)

Topic:

Overhead Line Electrification

Summary:

Our modelling capability for overhead line dynamics developed with Network Rail has been extended in work with Furrer+Frey focusing particularly on non-standard geometry for retro-fit of electrification to existing infrastructure. understandibg of overhead line fatigue and wear performance (neutral sections, contact wires) has been developed through laboratory testing on fatigue particularly for arc exposed materials. Current work focuses on low cost electrification options.

Project examples:

Arc Damage Identication and Effects on Fatigue Life of Contact Wires in Overhead Lines (2016-21), Transforming life and reliability of railway overhead power lines (EPSRC iCASE 2016-2021), Novel materials and installation configurations for low cost railway overhead line (2020-2024)

Topic:

Network Performance and Energy Modelling

Summary:

Resarch on network optimisation for traffic management (multi-train trajectory optimisations) has been extended from the pespectives of passener experience and network energy implications of particular service patterns. Deployment of lineside energy storage in the rail network is the focus of a major EPSRC project developing storage technology, plus the control algorithms to integrate this into road and rail traffic management systems.

Project examples:

TransEnergy - Road to Rail Energy Exchange (EPSRC, 2017-21), A methodology for passenger-centred rail network optimisation (EPSRC iCASE 2015-2020)*TransEnergy - Road to Rail Energy Exchange (EPSRC, 2017-21), A methodology for passenger-centred rail network optimisation (EPSRC iCASE 2015-2020)

Topic:

Station Design and Security

Summary:

Stations are often a target of terrorist activity. Through UK and EU funded programmes we have developed guidelines and training used by the Association of Chief Police Officers, the British Transport Police and Architectural Liaison Officers, on how to design resilience to attack into stations while remaining open and welcoming to travellers. A linked programme has developed mitigation technologies for blast containment for improvised explosive devices in the urban environment, considering the station situation in particular. Most recent work is in production of 3D visualisations to enable better understanding of how to deploy protective materials and technologies.

Project examples:

Innovative Solutions in Future Stations, Energy Metering and Power Supply (IN2STEMPO, 2019-21), ENCOUNTER - countering IEDs in the urban environment (EU, FP7)

Topic:

Passenger Movement Simulation

Summary:

Research is being undertaken using agent-based modelling of passengers in stations and trains. This is being conducted using massively parallel Graphics Processing Unit (GPU) simulations for parameter exploration and sensitivity analysis. Validation is through comparrison with CCTV footage collected from around the network (Liverpool, Leeds, Birmingham New Street, London Bridge and others). Initially this work focused on behaviour at the platform-train interface (PTI) but this has been extended during the pandemic to consider boarding and alighting while social distancing is in place. Outputs are supporting understanding of dwell times and time-proximity calcultions for passengers in a range of situations.

Project examples:

RSSB RateSetter platform-train interface flow optimisation (2017-21), UKRI Increasing rail transport throughput while avoiding compromise social distancing (2020-21)

Topic:

Longitudinal Stress Measurement in Rail

Summary:

We have developed a new longitudinal stress measurement tool based on ultrasound which has been taken from the lab to the field through projects with Network Rail and FRA in the US.

Project examples:

Network Rail In2Track2 project on rail stress measurement (July 2020 – May 2021), FRA funded project on rail stress measurement (Jan 2019 – Jun 2021), Network Rail funded project to investigate using ultrasound to determine longitudinal stress in a railhead (Jul 2014 – Dec 2015)

Topic:

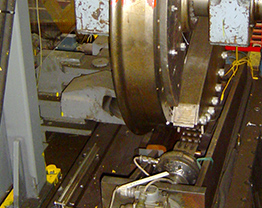

Innovative High Speed Rail Grinding Technology

Summary:

We have developed a new high speed rail grinding technique through a series of projects with Network Rail. Through UNRRIN investment we have also developed anew grinding test platform for assessing grinding parameters for conventional grinding approaches in collaboration with British Steel.

Project examples:

iCASE PhD with British Steel on rail grinding.(Oct 2021 – Sept 2025), Network Rail In2Track2 project on rail grinding (July 2020 – June 2021), Network Rail sponsored iT-CDT project on rail grinding (Oct 2017 – Sept 2021)

Topic:

Innovative Rail Head Cleaning Technology

Summary:

We have developed a unique rail head cleaning technology for application via road-to-rail vehicles ad rail head treatment trains. This has been taken from the lab through funding with RSSB to filed application with Network Rail, Northern Trains and Tyne and Wear Metro operators, NEXUS.

Project examples:

Network Rail funded track cleaning on West Highland Line Autumn 2020., SBRI First of a Kind 2020 rail head cleaning project (2020-2021), Network Rail funded track trials of rail head cleaning (2019-2020)